The iron and steel industry is one of the most burdensome environments in which components and power transmission equipment have to operate. Rolling bearings for foundries and steel mills must withstand the most varied and extreme operating conditions, including sudden changes in temperature, very different rotation speeds, strict lubrication requirements, high loads and exposure to moisture and contamination of heavy particles and corrosive substances.

Thanks to the knowledge gained through a significant commitment in the sector, KG is able to produce better bearings for rolling cylinder necks and to design and manufacture standard and special bearings for various applications related to steel processing, thus helping the customer to increase productivity, extend the mean time between failures (MTBF) and reduce operational costs.

Performances offered by the Dubai Company are radial bearings with one or more rows of cylindrical rollers and tapered rollers, medium and large angular contact ball bearings and double row tapered roller bearings. Dimensional precision (according to DIN 620) is normally P6, while rotation precision (defined by the same standard) is P5, even if special versions can be produced according to customer requirements or in the face of special conditions of use. KG offers radial bearings with 6 rows of cylindrical rollers with normal precision. The rings are typically produced in 100Cr6 or 100CrMo7 steel with hardness between 58 and 64 HRC.

KG cylindrical four-row radial roller bearings have lower friction than other roller bearings and are particularly suitable for applications where high speeds are required. The reduced radial dimensions of these bearings allows the adoption of large diameter necks with respect to the mill roll. The inner ring is free of edges; the bearing can therefore face, within certain limits, axial displacements of the shaft with respect to the housing. The rollers are guided on the outer ring between integral or non-integral edges. The bearing is separable, i.e. the outer ring and the cage form a single body and can be mounted independently of the inner ring: this facilitates the assembly and maintenance of the rolling mill.

KG is able to offer multi-row bearings for the cylinders necks of hot and cold rolling mills designed with a special bronze cage which improves the functionality of the bearing thanks to a higher load capacity, an increase in operating speed and lasting. In particular, the bronze cage used for heavy industry Series U bearings has the ground external center edge, in order to ensure that the cage itself is guided correctly on the inner central edge of the outer ring. This allows the power lost, due to sliding friction, to be reduced to a minimum, thus decreasing the operating temperature of the bearing. Depending on the application, bearings of this type can be supplied with a cylindrical or tapered bore. The rings, inner and outer, can be in one piece or in several pieces, in order to reduce the time needed to replace the bearings at the end of their life, thus lowering maintenance and downtime costs.

KG produces multitrack rings through a thermal process of stabilization called S0 that makes them suitable to support operating temperatures up to 150°C. On request other stabilizing heat treatments are available up to 200° C (S1) or up to 250° C (S2).

KG bearings with more than four cylindrical roller rows (and cages) are mainly used for large cold rolling mills for flat products, where rolling stresses are considerable and speeds are high (typically for cylinders with diameters over 220 mm). The outer ring has two non-integral edges, while the rollers are self-guided. Also in this case the inner ring is free of edges. The overall dimensions of the multi-row cylindrical roller bearings offered by KG are in accordance with ISO 15-1981.

The four-row cylindrical radial roller bearings are produced with radial internal clearance C3 or C4, while the six-row radial bearings have variable clearance depending on their use. On customer’s request, however, bearings with different clearances can be supplied. All bearings, which have a helical groove in the hole of the inner ring, are instead constructed with radial internal clearance C2.

For this type of bearings there is no type of misalignment.

For situations where there are dirt and contamination and with high operating loads, extreme impact loads, presence of high pressure water and flaky debris, the KG solution of four rows of tapered roller bearings in sealed performance is the best possible on the market to guarantee a long life. In fact, it allows a longer operating life and greater reliability, as well as higher load capacities than normal sealed bearings for rolling mill rollers used in this application. A further advantage is the reduction of the consumption of lubricants as well as the costs of disposal and purification of the refrigerant water.

In these situations KG uses cemented steel, i.e. subjected to a carbon enrichment of the surface layers (both of the rollers and of the tracks of the rings). Thanks to a high content of residual austenite and an increase in hardness, it is possible to obtain a longer service life even in conditions characterized by an insufficient oil film and by the presence of superficial damages.

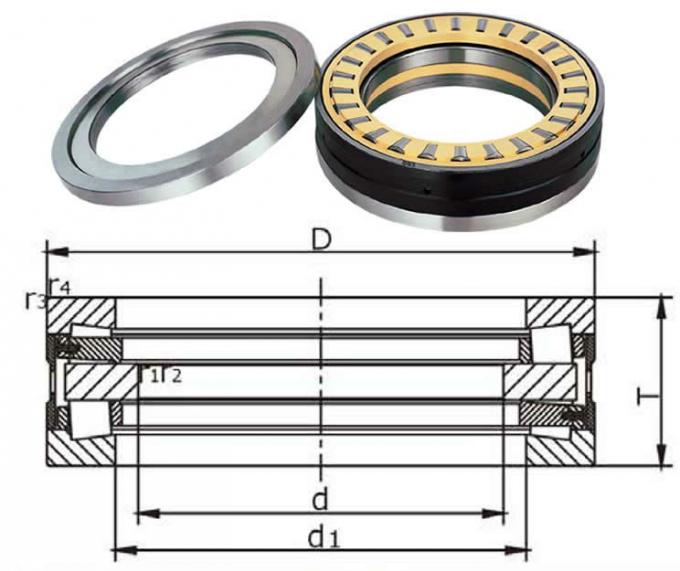

The tapered roller axial bearings with cage, which are separable, can be implemented by fitting the two sleeves and the cage roller assembly separately and easily. Double-acting ones are mainly used in rolling mills in combination with the multi-row radial types of cylindrical rollers. Since they are normally mounted with free coupling both on the neck of the cylinder and in the housing, to prevent rotation on the seat, the shaft washer/swelling ring is provided with one or two locking notches, in which to insert a key.

There are three types of settings. In the case of setting EZB.1, two central flat rings are used with a spacer in between: this solution is the most common and allows a slight eccentricity of the shaft with respect to the housing bore, of the same order of magnitude as the radial clearance of the radial bearing used.

The versions EZB.2 and EZB.3 have conical tracks on rings, so as to guarantee a greater load capacity than that with the central flat ring and to a certain extent can also radially constrain the shaft. The difference between the two is that the EZB.2 setting has a stop notch while the EZB.3 has two. The dimensions of tapered roller axial bearings have not been unified.

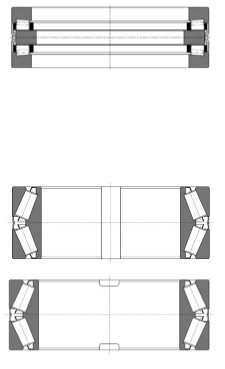

Fig. 1 –

Schematic representation of the 3 versions of tapered roller double effect axial bearings on the rolling cylinder neck (from top to bottom: EZB.1, EZB.2 e EZB.3).

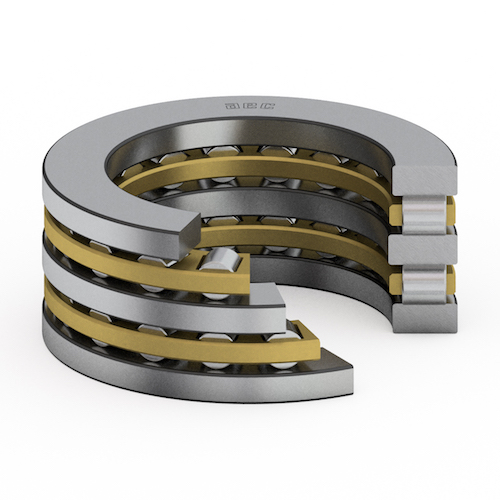

Photo 1: Thrust bearing double direction with cylindrical rollers (execution EZB.1)

KG is also able to offer other solutions for the iron and steel industry, including bearings for gearboxes, for lifting devices and for the support of rolling rolls (Sendzimir bearings). All this is possible through a just-in-time service thanks to the large stock available both in Asia and in Europe and to a production lead-time (between 60 and 90 days for all the types mentioned above) that does not have comparisons with the 9-12 months of production of the major competitors.

Photo 2: Thrust bearing double direction with taper rollers execution EZB.2

Photo 3 hot rolling mill

KG International FZCO

KG International (www.kginternational.com) is a multinational company with headquarters in Dubai, UAE, specialized in the production and distribution of both roller and ball bearings for multiple industrial applications. The company manufactures through factories in India and China and has two distribution centers, respectively in Dubai and in Hungary, through which it serves customers in Asia, Europe and Africa with a just-in-time policy. The company, founded in 1968 by Mr. Kedar Gupta, this year celebrates 50 years of life and boasts an annual turnover of over 60 million dollars. The main sectors served are transmission, agricultural machinery, heavy industry, electric motors and mining

For requests for information and quotations get in contact with ICT – International Consulting & Trading, who is responsible of KG business development in Europe: tel. +39 0121 376811 – e-mail info@consulting-trading.com.