PROSINO srl, partner of ICT srl in the supply of soft and hard rings for bearings, manufactures more than 9.000.000 steel rings for high precision bearings, mechanical applications and textile machinery per year.

Its secret is not only in its high performance turning machines, in the state of the art heat treatment, in customized vibro-polishing machines and in employees expertise, but also in the capacity of understanding customer needs beyond drawing specifications.

High precision bearings for machine tool application are heavily used in the Asian market, which is now the main producer of machine tool in the world. We are talking mainly about China, Taiwan , Japan and Korea. The approach to products in these market is different from Europe or USA. The product must not only be perfect from a functional point of view, but it also must look perfect, since any minimal visual imperfection would reflect into a non perfect product from manufacturing point of view. Such perspective is the starting point of our story.

An international super precision bearing maker based in Europe delivers its cylindrical roller bearings to OEM’s in Asia. The rings from Prosino were perfect, their performance was outstanding but … the customer noticed that the bearing grease tends to change colour after few weeks from the start of the life of the bearing in the application

Cylindrical Roller Bearings Rings

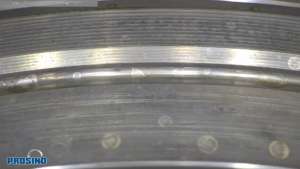

After long investigations the customer arrived to the conclusions that some contamination particles that were present on the undercut grooves of the inner rings were collected after heat treatment and subsequently combined with the bearing grease, changing its colour.

Unfortunately all the trials conducted at the customer site to clean the rings before or after the grinding process did not bring to any significant results. Prosino had to face the issue from another point of view: the undercut grooves need to be mechanically cleaned with a dedicated process. After many trials, the conclusion was that micro glass particles could allow to reach the desired level of cleanliness.

A dedicated machine was built and the result was astonishing. The rings were perfectly clean and the grease that the customer put in the bearings did not change anymore of colour, with a perfect satisfaction of the final customer.

This is an example how our company collaborates with its customer in order to build a win-win relationship.

Status before the cleaning

Status after the cleaning

ICT srl is official representative of Prosino rings. For any request of information and quotations, please get in touch with:

ICT srl

via Martiri del XXI 110 bis

10064 Pinerolo (TO) – Italy

Tel. +39 (0)121 376811

E-mail: info@consulting-trading.com

www.consulting-trading.com