To upgrade the manufacturing performances by European technology and automation

ICT srl (www.consulting-trading.com) is worldwide leader company in consulting worldwide bearings and bearing components industries under technical, organizational, strategical and commercial points of view.

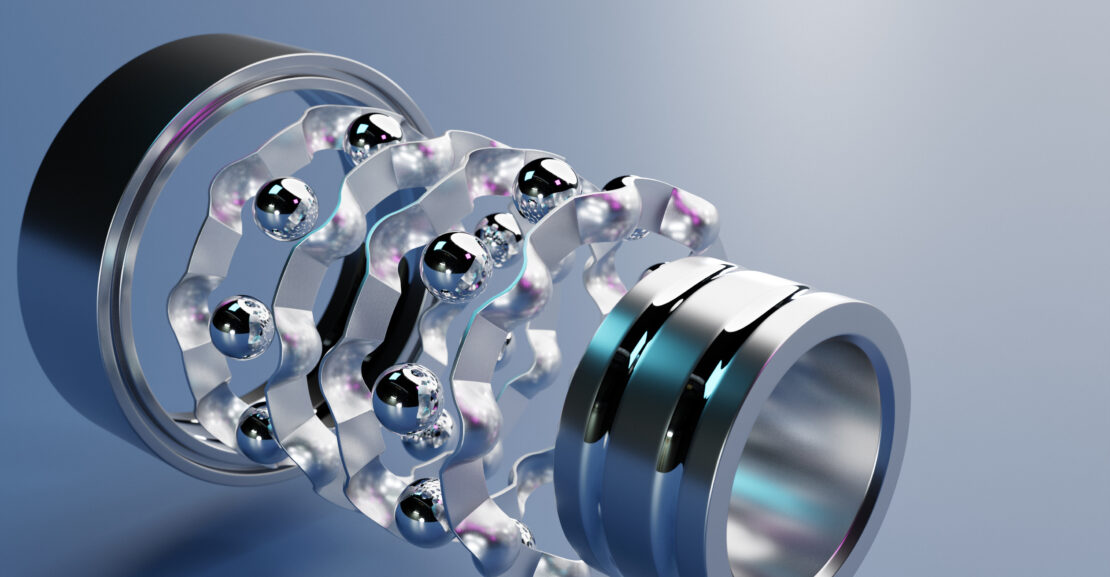

Since its foundation in 2012, company target has been to become a 360° partner of bearings industry, through the capability to serve such market with consulting services, machinery and tooling that range from strategic consulting to high quality bearing components, from grinding and lapping machines to abrasive wheels, from dressing tools to automation and quality control equipment. ICT engineers worked for many years within large multinational bearings companies and gained a rich experience in the best-in-class technologies and methods for manufacturing both ball and roller bearings, balls, rollers, cages and sliding bearings.

Thanks also to a strong practical knowledge of Lean Thinking methods, ICT engineers can assist the customers in:

- Introducing European best-in-class process automation both for manufacturing of bearings and bearing components, for quality control and for semi-finished and finished products fast and safe handling;

- Sourcing the proper equipment from Europe to reach the company targets in terms of:

- Finished product quality;

- Production output;

- Machine reliability and availability.

- Training the management, the staff and/or the workers to new technologies proper usage.

The process areas where ICT has proven track of achievements are in cold pressing, heat treatment, grinding, lapping, assembly, non-destructive controls and automatic visual inspections. Any manufacturing of DGBB, TRB, SRB, CRB and bearing components is within the scope of the consulting activity, both in the soft and hard side of the process.

For instance, the ICT capability to study in detail the best tooling design in cold pressing to get a net shape of headed components (like rings, balls, rollers, etc.) allows the manufacturer to reduce drastically the consumptions of raw material and – as consequence – to get benefits in terms also of reduction of electrical energy consumption and of shop-supplies usage and machine cycles for the following operations of grinding, as well as in terms of manpower productivity. The potential savings that can be achieved are counted in terms of millions of Euro per year per each value stream.

Furthermore, ICT supports customers in rethinking their production and logistics processes in order to minimize no added-value operations and to streamline their production flows. For example, the ICT engineers can assist in creating flow standards in accordance with the principles of the pull system to minimize inventory, production time and market delivery times. In this context, ICT can support in:

- definition of the main material flows;

- verification and sizing of any shared operation;

- relative calculation of optimal loop time and intermediate buffers;

- balancing production capacities;

- identification of a single bottleneck per each value stream.

Application of Value Stream Mapping (VSM) allows to eliminate or to minimize no added-value activities. Attacking waste, simplifying, Value Chain & Lean standardizing, motivating and innovating are the main daily activities in any leading company, to be implemented through continuous and repeated mini-projects in the field (kaizen), fundamental tools for the implementation of a real process of continuous improvement and involvement of all staff. ICT guides the customer teams in implementing daily such practices and to gain continuous improvement

Being lean means learning how to do the same things with less resources (people, goods, money, energy, etc.) or do more things with the same resources. Becoming lean means constantly increasing productivity (of labour, machinery, money, energy, etc.) through a virtuous mix of know-how and motivation. This is what ICT aims to do together with its own customers.

For more information of the results that can be achieved in your manufacturing units, get in touch with ICT experts writing at info@consulting-trading.com (stating in e-mail subject: “Know-how, Technology and Automation Consulting”) or calling at +39 (0)121 376811.